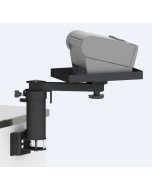

Wall Mount with a 3” Riser, 8” Arm, and a Flat Printer Tray

$250.00

In stock

Product Code

80025

| Product Code | 80025 |

|---|---|

| Availability | In Stock |

| Delivery Time | 1-7 Days |

| Note | Product usually ships within 24 hours of payment/order. |

- For complete specifications of this assembly; download the PDF Product Information Sheet; click the "Product Attachments" tab in the middle of this page.

General Features

- This wall mount can be used as a universal support system for most standard printers used for Point of Sale / POS, Kitchen Display Systems / KDS in commercial kitchens, retail, restaurants, offices, industry, shops, medical, maritime, schools, laboratory and many other applications.

- An innovative set of joint assemblies allow two axis of position adjustment on each arm when attached to a wall or other vertical surface.

- Beyond having flexible articulation; this mount has the key feature of being easily LOCKED in any desired screen position; this ability is VERY important when using touch screen equipment as it PREVENTS the screen from moving away from the user each time a touch is input.

- This arm of this assembly supports up to 15 lbs. This assembly is made of steel and is finished with a durable, black, low gloss, micro wrinkle powder coat that resists fingerprints.

- Visit kitchendisplaysystems.com for a free, easy to understand tutorial that covers all aspects of Kitchen Display Systems knowledge!

- This assembly is available in two configurations:

PN 80024 with 6” Riser + flat printer tray

PN 80025 with 3” Riser + flat printer tray - The single position mounting plate can also be attached to a pole up to 6” in diameter with an optional strapping kit P/N: 80801 or any compatible hose clamps.

- The single position mounting plate can be rotated and installed vertically or horizontally.

Flat Printer Tray on an Adjustable Arm

- A universal mount that works with most POS printers.

- The interior dimensions of the Flat Printer Tray are 6½” W X 10¼” L X 1” D.

- Includes a 1¼” diameter hole on one end for routing the power and data cables below the tray if desired.

- Includes multiple sets of tie point holes for inserting cable ties to secure the power and data cables if desired.

- Tightening the five- point knob below the end of the Arm applies variable resistance to allow adjustment of the side-to-side pan position of the Tray. A 10-32 Phillips head screw in one of the center holes can be tightened into one of the holes on the end of the arm to permanently secure the side-to-side pan position.

Riser, Riser Cap and Arm

- The Riser Cap allows an arm to rotate around the top of a Riser assembly.

- Loosening the three - point knob on the side of the Riser Cap allows adjustment of the side-to-side pan position of the arm around the riser assembly. Tightening the knob locks the position of the arm.

- The Riser cap incorporates a cable tie point to secure the cables so that they will travel safely as the arm is rotated.

- The Riser Cap interacts with the Riser Cap Stop on the side of the Riser to prevent the arm from making a full rotation around the riser. Refer to the Riser and mounting plate section for instructions on setting the position of the Riser Cap Stop

Single Wall Mounting Plate with Stand- Off Bracket, Riser, Riser Cap and Arm

- The Riser section elevates the arm above the mounting surface and permits the screen pan and tilt head, or printer tray, to travel horizontally allowing a wide range of positioning options.

- Attach the mounting plate to the Wall or other flat vertical surface with appropriate fasteners.

- Note that the Standoff bracket and arm can be attached to the mounting plate with the mounting plate in either vertical or horizontal orientation.

- Evaluate the side-to-side range of motion of the arm that are attached to the Riser Cap.

- The Riser Cap Stop prevents the Riser cap and arm from rotating a full 360 degrees around the Riser. It may be advantageous to relocate the stop position to optimize the side-to-side range of motion of the arm for your application.

- To reset the position of the Riser Cap Stop; slightly loosen the 5/16-18 bolt with a ½” wrench, slightly loosen the 10-32 Phillips head riser lock screw on the underside of the Stand Off Bracket; carefully rotate the riser to locate the stop at the new desired position; then retighten the bolt and screw.

- The Single mounting plate includes slots so that it can be attached to poles with compatible hose clamps.

- The Riser Cap incorporates a cable tie point to secure the cables so that they will travel safely as the arms are rotated.

We believe in ethical SEO relevancy; the following section was included to assist the all-knowing algorithms in locating this page; however, some humans like it too.

- Printer wall bracket, printer wall mount, printer wall mount bracket, printer wall mounting bracket, Printer Tray, Printer Shelf, Kitchen printer, restaurant printer, POS printer, Point of Sale printer, Epson Printer shelf, Healthcare printer, Industrial printer, ID printer, Office printer, Manufacturing printer.

| PN | QTY | DESCRIPTION |

| 50127 | 1 | SINGLE POSITION MOUNTING PLATE |

| 50046 | 1 | UVHM STAND OFF BRACKET STANDARD |

| 67048 | 1 | 8" Arm with three (3) 2-5/8" Washers |

| 67017 | 1 | 3" RISER ASSEMBLY |

| 67015 | 1 | Riser Cap Assembly |

| 70000 | 4 | Screw, 1/4-20 x 1/2" L, Phillips Round Head |

| 70003 | 1 | Bolt, 5/16-18 x 1-3/4 L Hex Head |

| 70004 | 1 | Screw, 10-32 x 1-1/2 L Phillips Pan Head |

| 70009 | 1 | Knob, Locking, 1/4-20 x 3/4"L 3 Point |

| 70011 | 2 | End Cap, 1", 10-14 gauge |

| 70014 | 1 | Spacer, Stop, 1/2" OD x 1/4" ID x 1" L |

| 70163 | 2 | SCREW, 1/4-20 x 1.25"L Pan Head Phillips |

| 70021 | 2 | Knob, 5 point, black plastic, 5/16-18 x 1-3/4" L |

| 70022 | 1 | Washer, Rubber, 1-3/4"OD x 5/16"ID x 1/16" Thk. |

| 70038 | 2 | WASHER, 3/4"OD x 11/32"ID x 0.05"THK Black Oxide |

| 70050 | 1 | SPACER, .375'' OD x .197'' ID x .18 THK |

| 70020 | 1 | Screw, 10-32 x 1/4" L Phillips Pan Head |

| 67090 | 1 | FLAT PRINTER TRAY |

Write Your Own Review